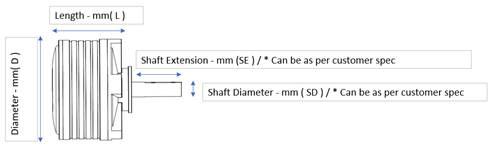

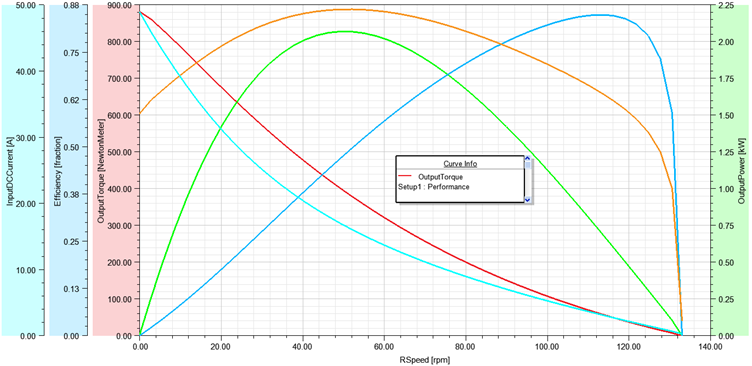

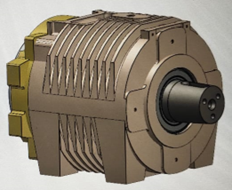

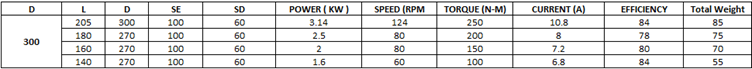

The multipole motor already has a very high-power density and thus has a very compact build. In addition, the drive consists of just two parts, rotor and stator, and there are no transmission elements. The motor has a dynamic startup performance and can quickly accelerate to the optimal output for the application. Hydraulic systems, with comparatively high lifecycle costs, lower system efficiency and higher heat development, incur significantly higher lifecycle costs.

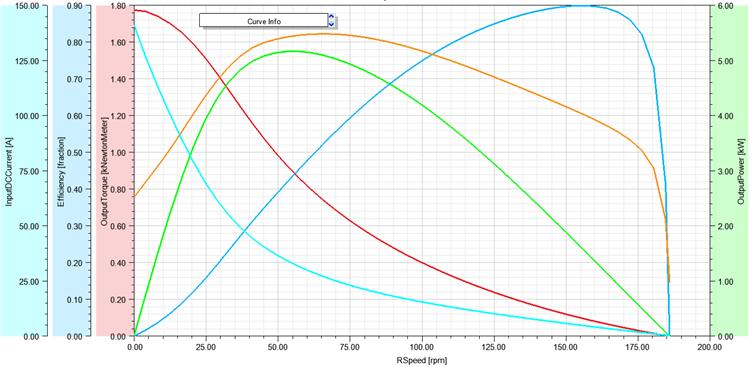

The speed and torque can be specifically controlled in the system.

The direct drive system is virtually oil free; the motor has a very long service life, and the lack of components means less susceptibility to faults. The second advantage in considering the lifecycle costs is the lower energy use. Here the direct drive can also excel over the gear motor, since first, the friction losses are lower, and second, it has a higher efficiency in the partial load range at a constant speed. This drive form thus also runs efficiently when changing frequently between partial and nominal load. You can save up to 50 percent of energy with this drive concept compared to traditional solutions.