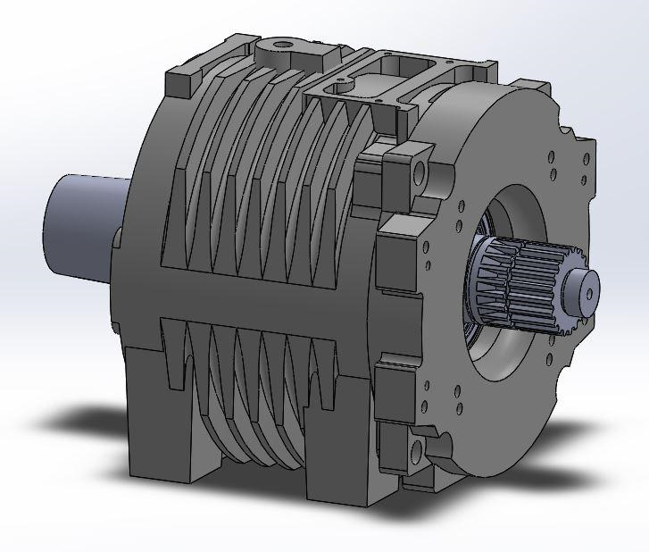

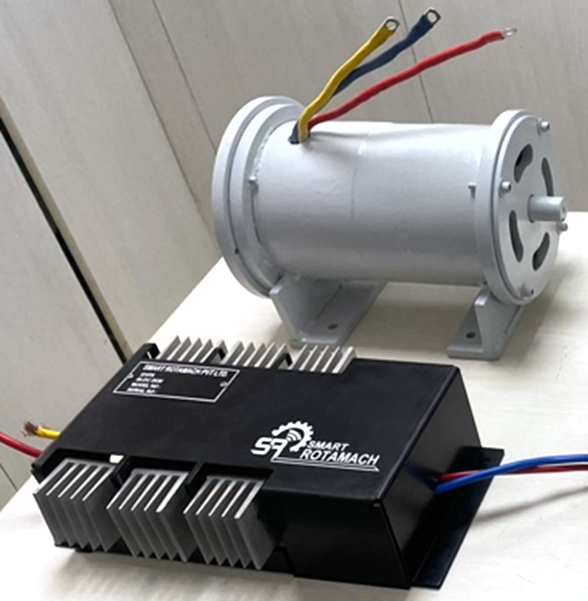

An elevator drive is a crucial component in elevator systems that controls the movement and operation of the elevator car. It is responsible for providing smooth and efficient transportation between floors. Elevator drives can be designed to work with sensors or without sensors, depending on the requirements of the specific elevator system. Our Elevator Drive is a 3 Phase 3.2KW drive designed to drive PMSM Motors, offering unparalleled performance and reliability in vertical transportation systems.